The Cetex Institute has developed a novel process and a first prototype system for the manufacturing of pre-impregnated unidirectional (UD) continuous fiber-reinforced thermoplastic prepregs (FRTP), entitled Ce-Preg®. The UD-FRTP prepregs form the basic material of the multidirectional lay-up to manufacture load-adapted multi-ply laminates within the in-line process. Compressing of the semi-finished sheets allows specific fiber orientations for 3D-contoured components.

Thermoplastic prepregs

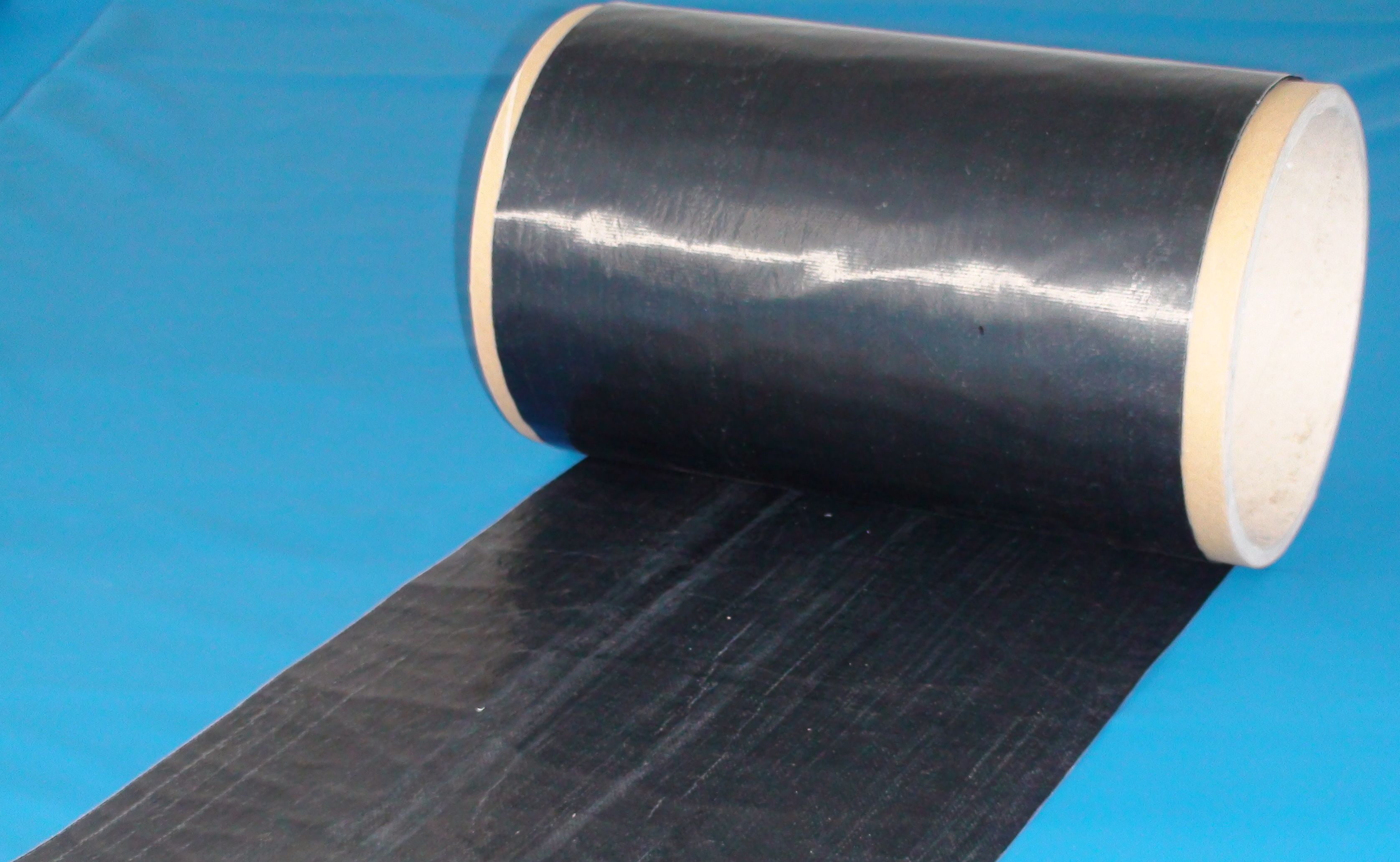

The thermoplastic prepreg material Ce-Preg® consists of one unidirectional aligned and flared ply of reinforcing fibers (carbon, glass, basalt fibres) embedded in a thermoplastic matrix (polyamide, polypropylene, …). These fibers are parallel-aligned and strung-out in the thermoplastic component taking advantage of the specific strength properties of the reinforcement. The reinforcing fibres are protected from damages through their embedding in the thermoplastic. According to the requirements on the composite components, various fiber-matrix combinations and different fiber volume contents can be realised. As a consequence, a wide range of variable adjustable composite properties can be achieved.

In the continuous production of the UD prepregs, thermoplastic films are applied on both sides of one layer of UD fibers with a defined area weight and hence the reinforcement is impregnated with thermoplastic melt. Thereby a flexible UD-FRTP prepreg with determined fiber volume content originates in its consolidated state.

Further processing

The semi-finished part consisting of an UD-FRTP prepreg can be further processed in this form or as a load-adapted multi-ply-laminate by means of a thermal forming process in a pressing tool as well as by fold-winding technology.

Downloads

contact person

Dipl.-Ing. Thomas Bauer

Head of Research Division Fibre Plastic Applications

+49 371 5277 225

Contact by mail