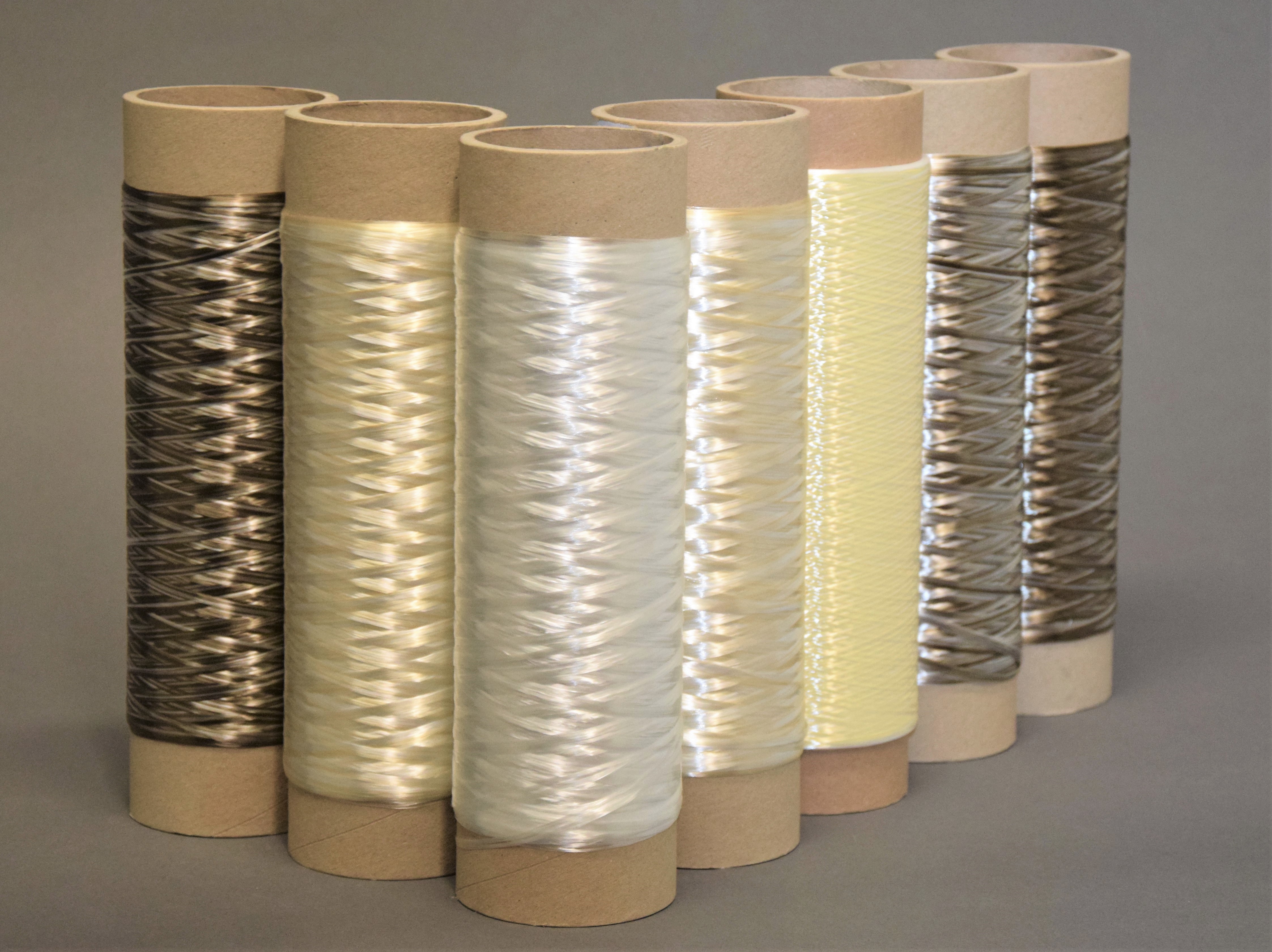

HYROV Hybrid Roving Materials

The basis for the innovative hybrid roving materials is a process for the highly flexible, continuous and effective production of hybrid rovings and hybrid tapes.

The processing of the matrix fiber and reinforcing fiber rovings is realized via an electronically controlled gate for the exact adjustment of the thread tension of each individual roving. The resulting constant roving tensile force and the spreading technology developed by Cetex enable homogenous mixing of the fiber rovings into a hybrid roving or tape with fully stretched roving filaments - without the use of compressed air.

The hybrid materials are not thermally fixed, whereby a classical textile processing in all possible applications such as, for example, braiding, wrapping, weaving, ... will be possible. Components with complicated shapes and Tailored Fibre Placement (TFP) structures can also be realised.

Through the homogeneous mixing of the reinforcing fibers with the matrix fibers short flow paths and thus a rapid impregnation can be realized.

The system technology enables a completely free combination of reinforcing fibers and matrix fibers to make application-adapted hybrid rovings and tapes. In collaboration with the manufacturers of the reinforcing fibers and the matrix fibers, tests were carried out to define optimal fiber-matrix combinations for different fields of application.

Technical details

- The hybrid roving materials consist of at least two different homogeneously mixed roving materials.

- The material can be either as a single roving or as a tape.

- Roving materials are all materials that are in fiber form.

- Material combinations:

- reinforcement fiber - reinforcement fiber

- reinforcement fiber - matrix fiber

- matrix fiber - matrix fiber

- reinforcement fiber - metal fiber

- fiber mass contents between 30 % - 60 %

- Lower energy requirements and lower costs during production

- Filaments of the hybrid roving produced are stretched and homogeneous, which means full utilisation of the mechanical properties

- Parallel production of several hybrid rovings possible

- Low fibre damage

- Flexible combination possibilities of different roving materials (also metal fibres)

- Use of bio-based systems for reinforcement and matrix fibres

- Textile character enables the laying of complicated component geometries

- Coating is possible depending on the application

Downloads

HYROV Hybrid roving materials

Product informationcontact person

Dipl.-Ing. Roy Gluthmann

Research and Development

+49 371 5277-229

Contact by mail